Most of the interest in our ground-breaking PrismJET VJ24 printer comes from people thinking about applications for which you don't need a large format printer. Some see it as a smaller version of its 'big brothers', the PrismJET VJ48 and MUTOH 1324 ValueJet. But it's not just a narrower PrismJET product. The VJ24 has a couple of unique features that open up tantalizing possibilities.

One of these is an application that has eluded digital sign makers for years. It's like the perpetual motion machine or calorie-free chocolate. We all want it, but no one has quite figured it out yet. The calorie-free chocolate of sign making is a way to digitally print on magnetic vinyl. Because it was co-developed with MUTOH's 426UF UV printer, The VJ24 has features that hold promise for printing magnetic media. In fact, it can print directly on some magnetic sheeting... but with several important caveats. Here are the dos and don'ts.

Promising Features: The two features the PrismJET VJ24/ValueJet 628 has that make it more suitable for printing directly to magnetic vinyl are its aluminum platen and superior head clearance. The lack of ferrous metal in the platen is the biggest advantage. This means there's no drag as the magnetic media is fed through the printer. It advances just like any other matte media. Other ValueJet models use ferrous metals. The magnetic vinyl clings to the platen. This of course interferes with the page feed settings, print quality, and generally makes a mess of things.

Magnetic vinyl manufacturers and McGuyver impersonators have suggested attaching overlaminate film or masking tape to the underside of the magnetic sheeting to defeat this. But, in our experience at least, nothing has worked...until MUTOH built their new 24" printer with a platen made of non-ferrous alloys.

The other feature that makes the PrismJET VJ24 a better choice for printing magnetic sheeting is its outstanding clearance. Like all MUTOH-made printers, the VJ24 has two head height settings. The lower setting is designed for use on photo paper, cast vinyl and other thin media. The higher setting is for banner media, six mil vinyl, etc. The maximum media thickness specification is 2.75mm", which translates to over 90mil. That's more than enough to print a sheet of 30mil magnetic sheeting...or so we hoped.

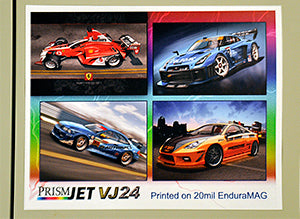

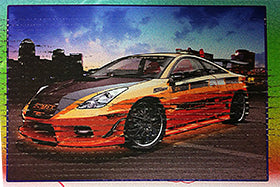

Promise Partially Fulfilled... One Step Closer: We did all of our testing with the head in the higher position of course. We started with a roll of 20mil DigiMag using our PrismJET 201 matte vinyl profile. The result was great print quality, no feeding issues, and no head strikes. And there was great rejoicing. But, while printing on 20mil magnetic media is fun, the chewy caramel center of the calorie-free chocolate in our tortured metaphor is 30 mil magnetic vinyl. This is what's used for automotive door magnets. They look good with vinyl graphics, but they can look even better-and be more effective--with digitally printed graphics.

Since most printers can't directly print magnetic sheeting, the current method used is to print on vinyl, then mount the vinyl to the magnet. Busy sign makers want to print them , trim them, round off the corners and sell them. Is the PrismJET VJ24 the tasty, trouble-free solution we've all been looking for? No. Here's why.

- 30mil magnetic sheeting is thin enough to pass through the printer, But it is also too stiff to lay flat as it rolls across the platen. The printer does have media edge guides designed to prevent this, but the edge guides are made for vinyl and paper. The 30 mil magnetic vinyl is too tall for the edge guides. Without the guides to hold it down, the magnetic sheeting tends to rise off the front of the platen and cause head strikes (Fig 1). The 20mil DigiMag works partly because it's thin enough to fit under the edge guides, which prevents head strikes. So unfortunately, 30 mil rolls are not usable. More importantly, these head strikes can damage your printer. And, since 30 mil magnetic media is not a supported application, any such damage is not covered by the printer's warranty.

- According to our contacts in MUTOH technical support, 30 mil DigiMag or EnduraMag can be safely fed through the printer in sheets... if they're flat. To make this work you have to cut he media into sheets about 24 hours before printing. This gives the sheets enough time to flatten. Then, the flat sheets can be safely fed through the printer. This course results in added material waste and a much slower turnaround time for your magnetic signs. The extra time and waste means printing on vinyl and mounting it to the magnetic sheeting is still the best choice.

Indoor Magnets with Considerations: As noted above, the PrismJET VJ24 printer will directly print 20mil magnetic vinyl with no feed or head strike problems. Why is this not good enough for car mags? 20 mil magnets aren't thick enough to generate the magnetic pull force required to keep the sign attached to a vehicle at highway speeds. So the printed magnetic media will be limited to indoor applications like refrigerator magnets, magnetic business cards, etc. If you really want a vehicular application, you'll have to settle for your kid's Barbie Car or GI Joe Jeep. But even with the 20mil magnetic media, there are two important considerations.

- Media width: The 24" rolls are actually 24-3/8" wide. The maximum media width of the printer is 24.4". So, theoretically, it should work. But it doesn't. It's too tight a fit to squeeze the 24.375" roll into the edge guards. This causes head strikes as the material is pushed upward at the edges (Fig 2). So loading a full width roll of 20mil DigiMag is a non-starter. Your rolls must be cut to a narrower width before printing. Although SignWarehouse does slit rolls of inkjet media, transfer tape, and vinyl, we do not slit magnetic media. Slitting magnetic vinyl degrades the blade and makes it harder to slit vinyl and tape cleanly.

- The other problem is the core. A 24.375" roll of magnetic sheeting comes on a wider core that suspends the roll in the box to protect it from shipping damage. You can't load that on the printer either. So you're going to have to slit the 24.375" roll of 12mil or 20mil DigiMag and its 28" core down to about 20" wide". Or you could pull a section off of the standard core, cut the DigiMag down to 20" width, and load it as a sheet. Or you could unroll the full length, trim it to 20", tape it to an empty 24" core, and print it directly.

Summary If you're starting to get the idea that this is more trouble than it's worth, you're not alone. That's what most sign makers have decided. That's why the standard procedure for producing digitally printed magnetic automotive signs remains printing vinyl and mounting it to the magnet. But, if you do want to print on magnetic vinyl your VJ24, it can be done. Just start with a 20mil roll of DigiMag, and have it slit to 20" wide on a 20" core. Just don't ask us to slit it for you. One of these days, some genius will invent zero-calorie chocolate, fat-free pizza, and a really good solution for printing on 30 mil magnetic vinyl.

PS: You can view the videos from our recent webinar on the PrismJET VJ24, below...