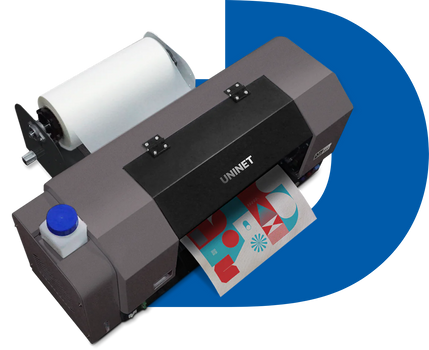

Ready to wear meets designer quality

The UNINET DTF 1000 is an ink-based direct-to-film digital transfer printing system with a roll feeder capable of printing up to A3+ or 13 inches wide. It is built to perform for the short-volume production of exceptional quality and full-color print transfers for the digital apparel decorating market, which can be applied to light and dark-colored garments.

Good things come in smaller packages.

This 13" print width, desktop-sized DTF printing equipment is compact yet powerful, expertly configured for manual DTF powder application, and capable of producing simple or intricate, colorful weedless digital transfers in a single pass. As an optional upgrade, the DTF™ 1000 can be paired with the* UNINET® DTF™ 1000 Auto-Powder Unit to enable fully automated powder application, curing, and drying for a comprehensive printing solution, transforming it into the most cost-effective DTF printing device on the market. (* UNINET® DTF™ 1000 Auto-Powder Unit is sold separately).

Product Features

High-Resolution Printing and White Overprint® capabilities

TheUNINET® DTF™ 1000 printing system has a high-definition, professional inkjet printhead with a wide color gamut for crisp, stunning print output. It also incorporates a technology that automatically lays down a combination of CMYK colors and white overprint® capabilities to produce professional-quality and sharp prints in one pass.

The UNINET® Seal of Quality

Every UNINET product introduced to the market is backed by the UNINET seal of quality, one of the world's most trusted printing solutions companies, for years. The same is true for the UNINET® DTF™ 1000. In the form of consumables, transfer film papers, and cleaning solutions, UNINET offers a comprehensive, all-inclusive functional solution to streamline the printing process and empower printing professionals to rapidly move from thoughts to see their creations come to life.

The UNINET® DTF™ 1000 Printing System comes equipped with the following:

- A high-definition and professional inkjet Printhead

- UNINET® DTF™ ProRIP™ Advanced RIP Software features exceptional file preparation, white and color management, production automation functionality, and more.

- UNINET® DTF™ Master Class Video Training Series: Discover everything there is to know about DTF printing, maximize the value of your equipment, and be inspired to expand your business even further.

- UNINET® DTF™ Five-color inks (CMYK + White)

- UNINET® DTF™ Powder

- UNINET® DTF™ Film Roll – 100 meters

In Addition, the printing system features

- Printer Roll Feeder with auto-feeding capabilities

- Ink tanks with Continuous Feed System

- Bluetooth Humidity and Temperature Sensor

- Internal Controllable Vacuum Suction (prevents film buckling)

- White Ink Circulation Engine (helps circulate white ink)

- UNINET® DTF™ 1000 Auto Powder Unit, as an optional upgrade, can be paired to the DTF™ 1000 transfer printer to enable fully automated powder application, curing, and drying for a comprehensive printing solution. (Optional upgrade is sold separately)

BEYOND THIS, UNINET PROVIDES

- UNINET DTF Cleaning Solutions

- UNINET DTF Inks

- UNINET DTF Transfer Film Papers

- UNINET DTF Powders

- USA Training and Technical Support*

- UNINET DTF USA Warranty

* Onboarding technical support included in USA and Europe; additional technical support required purchase or a subscription plan

A LOOK AT THE NEW UNINET DTF PRODUCT LINE

Specifications

| Specifications | |

|---|---|

| Printhead | A high-definition, professional piezo inkjet printhead |

| Maximum Resolution | 5760 x 1440 dpi |

| Ink Type | CMYK+ White with bulk ink system |

| Cartridge | 500ml bottles |

| Print Speed | 6 to 8 minutes A3 Sheet |

| Media Capacity | 328 ft (100m) PET film roll: 13 in (33 cm) |

| Maximum Media Width | 13 " (330mm) |

| Interface | USB |

| Rated Current | 5A |

| Rated Power | 500W |

| Dimensions | 28"W x 23"D x 13" H (711 x 584 x 330mm) |

| Shipping Dimensions | 36" X 15.5" X 13.5" (914 X 394 X 313mm) |

| Weight | 48lbs (21.8kg) |

| Shipping Weight | 60 lbs (27.2kg)* |

| Bundled Software | UNINET DTF ProRIP |

| Compatible OS | Windows® 10 & Windows® 11 |

| Warranty | USA Warranty, parts & labor |

| Included with Printer | CMYK+W Bulk Ink system, DTF 13" x 328ft roll of transfer film, DTF white adhesive powder, maintenance solutions and accessories Certificate for DTF Master Class Video Training. |

Contents

- UNINET DTF1000 Desktop Direct-to-Film Printer

- DTF ProRip Software, 500ml ink bottles, Film, White Powder, & Supplies

- UNINET 14” x 20” Heat Station

- UNINET 3-layer HEPA-filter, 106CFM Fume Extractor

- SilverBolt 1620-SA Premium heat press & floor stand

- 15 Assorted Bella Cotton Shirts

- DTF Master Class Video Training + Personal Setup Assistance

- One year of Complimentary Gold Support

- 90-Day depot warranty

UNINET DTF Heat Station Features:

- CE rating for reliability assurance

- Easy to use push button control panel

- Configurable for Fahrenheit or Celsius.

UNINET Fume Extractor Features / Specifications

- 80W motor 106CFM Fume extractor

- 99.91% Purification Rate | The 80W DC motor creates a powerful 106 CFM airflow to exhaust and purify the air.

- Flexible Air hose.

- Three-layer filter system with cotton, HEPA, and activated carbon filters.

- Three-speed motor to adjust for more demanding environments.

- Low-noise brushless motor for quiet operation: less than 55dB @ 5800 RPM.

- Compact and mobile for use in home & office. Additional room ventilation is highly recommended.

SilverBolt 1620SA SPECIFICATIONS:

- Platen Size: 16" X 20" (40 X 50cm)

- Control Interface: 4.5” Digital LCD

- Maximum opening height: 2" (5cm)

- Time Range: 0 - 999 seconds

- Temperature Range:

- Voltage: 110V

- Power: 1600W

- Maximum clamping pressure, 771lbs

- Gross Weight: 149 lbs (67.5 kg)

- Floor Stand: Included

Things you may need that are NOT included: Small funnels and humidifier.

*NOTE: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use protective gear since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.