Maintaining your printer properly is just like taking proper care of your car. If you change the oil regularly and follow the manufacturer’s maintenance schedule, you’ll get many years and miles out of your vehicle. Likewise, adhering to PrismJET 54 recommended maintenance best practices will yield many years of profitable printing. Many calls to SIGNWarehouse Product Support could be avoided by proper printer maintenance.

We are committed to your success and will always assist when needed, but the best option is to take proper care of your printer. Just as regular oil changes and scheduled maintenance can protect your car’s engine, regular cleaning and maintenance of your PrismJET 54 Gen2 printer can prevent costly repairs and down-time. Here’s what you need to do to keep your PrismJET in tip top shape.

PrismJET 54 Recommended Maintenance

If your sign business is up and running, the most important thing you can do to keep your printer up and running is make sure your maintain it properly. This means regular cleaning of the main components, and periodic inspection and/or replacement of consumables like the capping station. Here’s the breakdown of what should be done and how often.

• Cleaning Cycles: Running a cleaning cycle is just as easy as printing a nozzle check. Press and hold the right arrow button on your PrismJET 54 control panel for two seconds to initiate a cleaning cycle. Then print a nozzle check and inspect the outcome. If the nozzle check is perfect, you’re good to go. If you have clogged nozzles, you will need to repeat the cleaning cycle. If the nozzles remain clogged after two cleanings, you may need to perform a powerful cleaning. This is also done from the control panel menu. You can choose from normal or powerful cleanings or a “little charge” which forces even more ink through the head. Detailed instructions on initiating a powerful cleaning or Little charge can be found in page 182 of the User Manual.

• Sleep Mode Auto Cleaning: The Sleep Mode function in your PrismJET 54 Gen2 helps to conserve power and to preserve the life of the print head. You can program the printer to go into sleep mode and power down after a specific period of inactivity. During sleep mode, the printer will still run cleaning cycles at programmed intervals. can be programmed to run cleaning cycles automatically. Auto cleaning can be set from one to 24 hour cycles. For most users, we recommend setting this at 12 hours.

In order for the auto cleaning function to work, the printer must be left powered on when not in use. There’s a caution here. Don’t rely entirely on auto-cleaning to keep your head in good condition. You still need to fire the head periodically and print frequently enough to keep the ink delivery system in optimal condition. Refer to the Recommended Usage sticker on the inside of the front cover of your printer, or click here for full details. Auto cleaning is just a nice backup. More detailed instruction on setting the auto-cleaning intervals can be found on page 187 of the User Manual.

Manual Cleaning

Auto-cleaning cycles are not enough to properly maintain your printer. These only prevent buildup of ink in the nozzles. They don’t remove ink residue that accumulates on the print head carriage, wiper, or capping station. These components must be cleaned manually and regularly. Clean around the print head, clean the wiper, and the capping station. These are manual processes that must be done weekly. Only use the maintenance swab supplied with your printer (referred to as a 'cleaning stick' in the user manual), and follow the instructions in the User Manual carefully. At no time should the cleaning stick touch the bottom of the print head (nozzles).

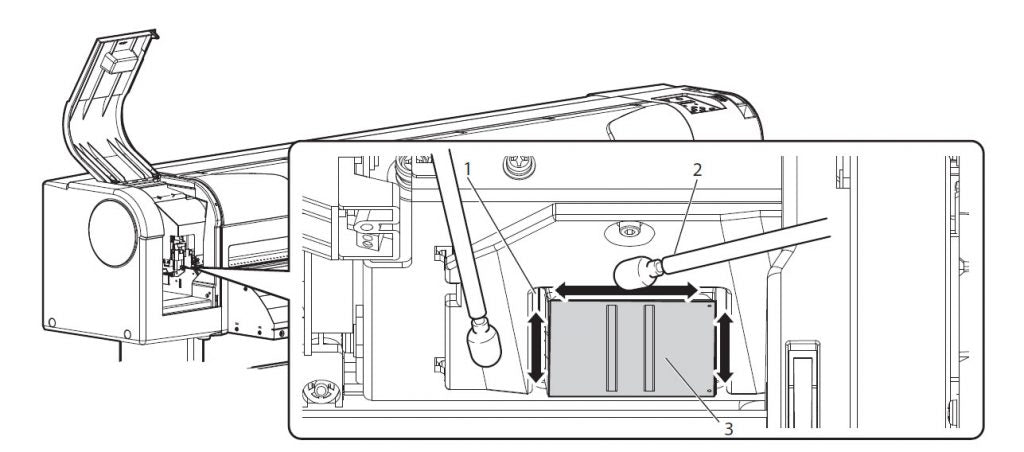

• Cleaning the Wiper: The wiper is small rubber blade that cleans the print head. It’s mounted on the left side of the capping station and is positioned to rub the bottom of the head as it passes over to mount on the capping station. You can think of it as a tiny squeegee. But there’s no tinier squeegee to clean this little squeegee, so you have to clean it manually. In the PrismJET 54 Gen2, this is a user replaceable part that must be inserted during printer setup. Your printer is shipped with three wipers. They're easy to insert, replace, and clean. Use a maintenance swab and some approved cleaning solution to wipe ink residue from the front and back of the wiper blade. When the wiper accumulates too much ink residue and cannot be cleaned thoroughly, replace it with one of the wipers shipped with the printer or order a new one online. (FIG 1).

• Clean the Cap Top: Once or twice a week during normal use, you should use a dry maintenance swab to remove ink residue from the rubber seals around the top of the maintenance station, also known as the cap top or capping unit. Keeping the cap top clean ensures a good seal is maintained between the cap top and print head. Do not touch the Rubber Cap or the maintenance swab. Oil from your hands may prevent the cap from sealing properly. Do not allow the swab to touch the pad in the center of the capping unit. Only the edge seal should be cleaned.

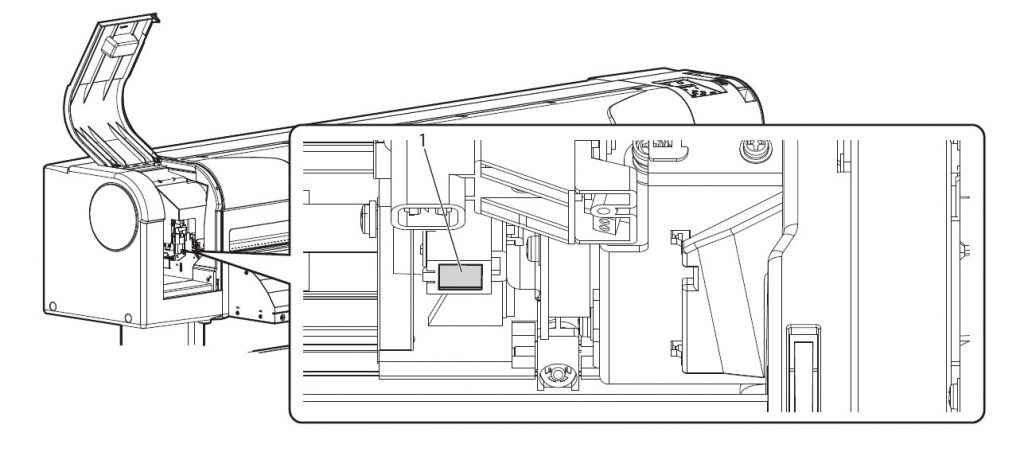

• Clean Around the Print Head: Even if the wiper and maintenance station are cleaned regularly, it’s a good idea to clean around the bottom of the print head and carriage. The process is similar, but you’ll need to use the printer’s control panel to move the head assembly to the maintenance position in the far left side of the printer. Do this by pressing the setup menu and scrolling to the Maintenance option. Press the Menu key and enter the Setup menu. Use the up/down arrows to scroll to Set17: CR Maintenance, and press Enter. The head will move to the open area to the left of the platen. You can then open the access door in the front panel to reach the areas around the head carriage (Fig 2 below).

Use the swab to clean carefully AROUND the bottom of the head. Do NOT rub the button of the head itself (FIG 2). Your only goal here is to remove accumulated ink residue from the areas around the head itself and from the head guide (the leading edges of the carriage). Ink buildup here can prevent a good seal on the cap top and cause error messages, loss of vacuum, and eventually damage to the head. This should be done at least once a week. If you’re running your printer more than six hours a day, five days a week, this should be done more frequently. Please refer to pages 251 - 255 of the User Manual for more important information about cleaning around the print head

• Cleaning the Color Sensor: The PrismJET 54 Gen2 has a color sensor that is integral to operation of the automatic bi-directional head alignments and media barcode feature. In order for the automatic adjustments and barcode reader to work properly, the sensor must be clean. If automatic print calibration fails, it may be due to dust or debris on the bottom of the sensor. Please refer to pages 258 - 264 of the User Manual for more detailed instructions on cleaning the color sensor. See Fig 2 below.

Waste Ink & Replacement of Consumables

Just as a vinyl cutter needs replacement blades periodically in order to function well, your PrismJET 54 needs certain parts replaced regularly. There are several components on the printer that are considered consumables. They should be serviced or replaced regularly to support proper function of the printer. These includes the waste ink tank, wiper, cross-cut blade, and maintenance assembly.

• Wiper Blade. Even when cleaned regularly, the wiper blade will eventually wear out. When this happens, it will begin to fail to clean the bottom of the print head. This causes excessive ink buildup on the head and carriage, which can lead to errors including a (capping station error). If this occurs, clean the head and carriage thoroughly, then inspect or replace the wiper blade. As noted above, the PrismJET 54 Gen2 wiper is a separate component that is easily replaced. See Fig 1image carousel above. They’re inexpensive and readily available online.

• Replace the Maintenance Station: Even when properly cleaned and maintained, eventually normal wear takes a toll and some components need to be replaced. The maintenance assembly or capping station, should be replaced annually. The rubber seals that create vacuum under the head will eventually wear out. When this happens, air leaks in and the head dries out. If this is missed, by the time the damage is done, you may need to replace the print head. So do yourself a favor and make sure to change this critical component annually.

• Waste Ink Tank: During cleaning cycles, ink is pulled through the maintenance station down into the waste ink tank. Eventually, the waste ink tank will need to be emptied. How do you know when to do this? Easy – the printer will tell you to. As the tank fills, a “Near Full Waste Ink Tank” warning will appear on the printer’s LCD control panel. When the tank is full, a “Full Waste Ink Tank” message will appear, prompting you to empty, then reset the tank. Emptying the waste ink tank is as easy as turning on a garden hose. Simply turn the valve on the hose to allow waste ink to flow (FIG 3). It should flow into an approved container so that the ink can be disposed of responsibly in accordance with local ordinances for disposal of chemicals.

Recommended Usage: Keep it Flowing

Finally, the last thing you can do to keep your printer in good shape, is to use it. Printing keeps the ink delivery system in the pink, so to speak. For detailed recommendations on what you should print and how often, check out our recommended usage article.

Your large format printer is an important investment. It makes sense to take good care of it. Just as regular maintenance is essential for getting maximum mileage from your vehicles, proper maintenance is essential for getting the best experience from your PrismJET 54 Gen2 printer. Taking proper care of your printer with regular cleaning, replacing parts as they age, and keeping it printing, will produce the best mileage from your large format business engine.