Surely you've heard of New Yorkers who've never been to the Statue of Liberty. This article isn't about New York, but it's the Sign College equivalent. We've published over 400 articles during the years, all of which are designed to educate our customers. We have basic guides aplenty but somehow, we have overlooked one of the most basic questions about digital sign-making. It's a question we hear on a regular basis. 'What is Punched Vinyl?' I know, right. If you're an experienced sign maker, you could probably write this one yourself. If you're scratching your head thinking, 'what the heck is punched vinyl', this article is for you. We'll bring you up to date on the history, purpose, pros, cons, and aliases of punched vinyl.

Punched Vinyl: What and Why

The story of punched vinyl is the story of the advent of digital sign making. The first computer-driven vinyl cutter came to market in 1982 when Gerber Scientific introduced the SignMaker III. The SignMaker III used a tractor feed or pin feed system to advance adhesive-backed rolls of vinyl. These are similar to old dot matrix printers used in office settings of that era. If you've been to a NAPA store recently, your receipt may have come from a printer using the same system.

Anyway, the vinyl had to have holes punched in the edges in order to fit over the SignMaker's sprockets. This is the basic meaning of the term punched vinyl. It's also referred to as perforated vinyl because of course the edges are perforated. And some just call it 'perf'. Bet you thought we were kidding about the aliases. So that's the 'What'. Now you may be wondering why this stuff is still around. The 'why' is simple. Gerber sold lots and lots of plotters. They had help.

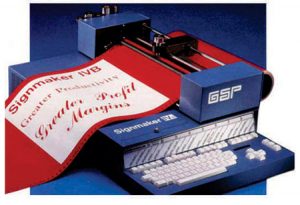

One of the earliest resellers was a young startup company called Vinyl Express, located in Sherman, TX. Yeah, that's us. In fact, we have a few customers who are still using Gerber IVB plotters (Fig 1) they bought from Chris and Erik Gripp back in 1984. SignWarehouse has been an integral part of the digital sign making industry for over 30 years. But enough with the history lesson. The other relevant question is 'what happened?' Why isn't all vinyl still punched or perforated? In short, nobody's perfect. Despite being revolutionary technology, tractor-fed plotters have drawbacks. Time for a brief look at the pros and cons.

Punched Vinyl: Pros & Cons First the upside. Tractor-fed vinyl cutters provide outstanding tracking. They keep the vinyl perfectly straight by virtue of the sprockets through the perforations. The downside is that, you always have to load a new roll of vinyl. And it has to match the fixed size of the plotter. The early Gerber plotters were 15" machines. If you have a 15" plotter and you need to make taller letters, you have to tile them together, which adds cost and complexity.

Gerber added a 30" model to accommodate the need for larger letters, but that also exacerbates the other downside of having to load 15" or 30" vinyl. Waste. What happens if you only need a 6" letter? What happens to the rest of that vinyl? It's not the most economical approach to sign making. And sign makers are nothing if not economical. The market cried out for a more pragmatic approach and other manufacturers filled that need with friction fed plotters.

The Power of Pinch Rollers

Friction-fed plotters use pinch rollers and a grit roller to squeeze the vinyl and hold it in place. (FIG 2) The main advantage of friction-fed plotters is their flexibility. Users can adjust the positions of the pinch rollers to hold and cut vinyls of varying widths. You can even load scraps if they're large enough. Goodbye waste! Because of these advantages, most vinyl cutters sold today use a friction-fed system.

While tractor-fed plotters still hold an advantage in tracking performance, the best modern friction-fed vinyl cutters produce tracking that goes beyond what most sign shops will ever need. The Vinyl Express Q Series for instance, comes with a 50-foot TrueTrack Guarantee. The versatility of friction-fed plotters lead to a wider variety of standard vinyl widths. Today SignWarehouse offers vinyl ranging from 8" to 30" wide. The vast majority of vinyl used today comes in 12", 15", or 24" rolls. This brings up another drawback to tractor-fed plotters. If you're limited to 15" perf, there are lots of awesome products you just can't use.

Why is it still here? Since friction-fed vinyl cutters and non-punched vinyl have pretty much taken over the market, you might be wondering why your 15" rolls of 651 still have holes in them. It's a matter of preference vs. necessity. If you have a friction-fed plotter and you get a roll of punched film, you might need to adjust your pinch rollers inward a smidge for optimal tracking. Yes, this means your 15" roll is now effectively 14" or so, but that's usually not a deal-breaker.

Getting a roll of punched vinyl may be an inconvenience, but it won't bring your shop to a grinding halt. But, as noted above, there are still sign shops out there using their old Gerber 4B. And Gerber is still in business selling - you guessed it- tractor-fed vinyl cutters. And anyone who owns one of these delightful devices HAS to have punched vinyl.

So some vinyl manufacturers, including ORAFOL, have defaulted to perforation in deference to their Gerber using customers. So now you know what punched vinyl is, and why it's still around. And we apologize for taking so long to get to it. If you're a New Yorker who's never been to the Statue of Liberty, we're sure you'll understand.