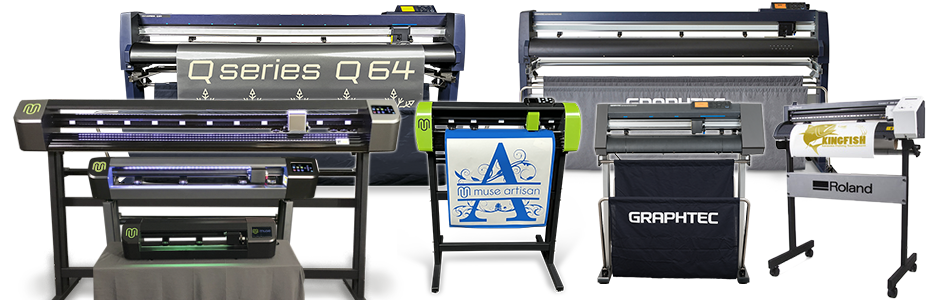

Choosing your first vinyl cutter is one of the most important decisions an aspiring sign maker faces. A professional quality plotter can make your dreams realities. A bad equipment decision can lead to frustration and failure. The most common start-up sign shop mistake is buying based only on speed, force, and price. Ten years ago, that wasn't a bad strategy. In the 21st century, you can buy a machine with 500 grams of force that can’t cut the mustard in a professional sign shop. So what are the criteria for making this important decision? What drive motor should your cutter have? How important is tracking? Do you need to contour-cut printed images? What other features do you need? What about tech support? To provide these and other answers, we humbly present this guide to choosing your first vinyl cutter.

Drive motors: Stepper or Servo

The engine of a vinyl cutter is its drive motor. The drive motor powers the grit roller that advances and retracts media and moves the blade across the platen. The two kinds of drive motors used are mechanical stepper motors and digital servo motors. As the name implies, a mechanical stepper motor moves in small increments or steps, driven by physical gears. It’s an old, familiar technology whose main advantage is economy. The downsides are mechanical noise-which can sometimes be quite harsh- and loss of precision on very small graphics. Large images can be cut accurately, but on characters smaller than a half-inch, the physical size of the gears prevents the machine from being able to plot the path smoothly. This may cause jagged lines that look pixelated instead of smooth arcs. Stepper motors are more economical and allow manufacturers to produce usable vinyl cutters more affordably.

Most entry-level plotters use this older, simpler mechanical drive system like our most recent addition, the MUSE Artisan. The Graphtec Silhouette Cameo series, CE Lite-50 desktop cutter, the Vinyl EXPRESS R Series cutters, and the new MUSE vinyl cutters all use mechanical steppers. As with most things, there are variations in quality among stepper-driven cutters. Some are quieter and more precise than others. The micro-steppers used in the CE Lite-50 and MUSE M15 and M24, for instance, produce surprisingly precise graphics without the noise normally associated with stepper motors.

In cutters driven by digital servo motors, a digital encoder translates the software’s commands into ones and zeros. The result is smooth, precise movement of the drive motor and cutting head. This offers three advantages. The lack of mechanical gears makes these machines much quieter in operation. More importantly, the digitally directed movement allows the cutter to turn and pivot along much smaller paths with precision. Letters as small as 1/8”* (*Helvetica med. font) are cut just as precisely as larger characters. Trying to cut characters that small with a stepper-driven cutter results in rough edges that are generally not satisfactory to discerning customers. The other benefit of digital servo motors is superior tracking. Tracking is a cutter’s ability to maintain a straight path along the length of the vinyl. Digital servo driven cutters typically achieve up to ten times better tracking than stepping cutters So digital servo cutters are a better choice for graphics both very large and very small.

Tracking

The drive motor isn’t the only element affecting tracking capabilities. The quality of the pinch roller assemblies, presence or absence of a floor stand, and features in the control panel all play a role. As noted above, tracking is critical for efficient production of medium and long graphics such as banners, pin-striping, and partial vehicle wraps. Inferior tracking leads to wasted time and wasted materials.

To choose the right cutter, it’s imperative that you know what size graphics you’re going to produce. If your business plan is based on scrap book and hobby sized decals, a simple entry-level cutter may suffice. If your plans include graphics less than ten feet long, a desktop or entry-level cutter like an R31, CE Lite-50 or MUSE M15 may be all you need. But if you intend to cut vehicle accent striping, partial wraps or anything else over 10 feet long, it would be wise to invest in a cutter with better media handling and tracking capabilities (Fig 1).

If you look at manufacturers’ specification charts, you’ll see a value called “maximum cutting area”. Don’t confuse this with tracking. Here’s the difference between maximum cutting area and tracking, according to Graphtec product manager Neil Zdunkawicz. “Basically, the maximum cutting length means the cutter, whatever brand, will be able to move that length of media and it won’t skew or jam; however, the quoted accuracy and repeatability specs are not guaranteed if you do that. The longest distance that can be cut and still meet the specifications, whatever they are, is the shorter distance. Due to the wide variety of substrates, blades, and operating environments, manufacturer’s typically detail the conditions used to achieve the quoted specifications.” Please review the table below to assess the comparative tracking capabilities of the vinyl cutters we offer.

![]()

Other Features:

Considering drive motors and tracking may be all the information you need to make a good decision. But if you’ve determined that you need a plotter that will accurately cut small fonts and consistently track in excess of 15 feet, you may still need to narrow the field a bit. Now what? There are other features found on cutting plotters that can greatly impact your productivity. To help you select your best 21st century cutter, here are a few more important criteria to consider.

- Tangential emulation can be crucial for producing quality stencils for sandblasting monuments or HDU. In normal “drag and swivel” cutting modes, the blade follows the direction of the blade holder, swiveling and pivoting as it cuts. When cutting thicker materials, this can cause the blade to get bound in corners. This can damage the blade holder and produce incomplete cuts that are difficult to weed. Full tangential cutting lifts and rotates the blade at corners to prevent this, but slows production and causes an annoying problem called “vinyl ears”. Vinyl ears describes the corners of the vinyl beginning to lift as the graphic is cut. Tangential emulation intelligently orients blade direction — without the blade leaving the face of the media. So angled cuts are more precise, and intricate graphics in thick media are neat and easy to weed. This precision is achieved without any loss in speed or productivity. This advanced technology is available on the Q Series and Graphtec FC9000 series cutting plotters (Fig 2).

- Contour Cutting: As digital printers become more commonplace in the sign and graphics industry, the demand for cutters that can turn printed images into contour-cut decals continues to grow. This is increasingly important for garment decorators who sell printed T-shirt transfers made with printable heat transfer vinyl. The process requires advanced hardware that enables the plotter to optically detect printed registration marks (also known as crop marks) and align the origin of the cut job so that the blade’s path traces the contours of the printed image. The plotter should also be capable of accounting for skew so that the cut path aligns correctly over the printed contours even if the media is loaded in the cutter imperfectly. This feature is found on an increasing number of plotters ranging from the humble Silhouette Cameo to Pro Series products from Roland and Graphtec. Different manufacturers use different terms, but all of these technologies require the use of integrated and capable software. Make sure you get the complete package. Buying a cutter with ARMS but not getting the right software is like buying a high-powered sports car without a steering wheel. Click here to read more about the kind of software you'll need for print and cut graphics. Here’s a quick summary of vinyl cutters that include this feature. ARMS* is standard equipment on the all MUSE vinyl cutters, and all Vinyl Express cutters except for the R Series. So everything from the MUSE M15 to the Vinyl Express Q64 has built-in firmware for automatic contour cutting. This is not the manual crop mark function found on some low-end Asian imports that requires you to find each registration mark yourself. These are sophisticated automated systems that sync with LXi, Flexi, or Create Space software to find the marks and cut out the images in one smooth, automated workflow. All Graphtec cutters including the Silhouette Cameo scrap-book cutter, and the CE7000-40 desktop cutting plotter come with some level of contour-cutting. The CE and FC series cutters are equipped with Graphtec's ARMS 8.0 firmware. ARMS 8.0 reduces waste by enabling contour-cutting inside the crop marks. It also expands your creative options because the advanced sensors work on a wide range of media, including glossy and reflective surfaces. Roland Stika hobby cutters have a manual crop mark sensor and Roland’s Camm-1 and GR Series cutters now come with registration mark sensors. The CAMM-1 GS24 firmware only supports three crop marks with a maximum distance from front to back of 24". So, to ensure correct print and cut alignment, keep your image files small. Don't send a three-foot long batch of prints to be contour-cut. This cutter works best when contour-cutting small format images like T-shirt transfers. The GR Series cutters use a more reliable Quadralign system that reads four marks and enables longer print and cut jobs. *Advanced Registration Mark Sensor

Fig 3: Advanced Cutters like the Q series and Graphtec FC-9000 machines can produce 'pop-out' decals

- Perf Cutting: The ability to both cut and perforate vinyl can win lucrative jobs for decal production. This is a two-step process requiring a cutter that can perform a traditional “kiss cut” (cutting only through the face film) followed by cutting all the way through the face film, adhesive and liner - all without damaging the platen (Fig 3). This 21st century function requires a specially engineered platen and tool holder. These features are found on the Vinyl EXPRESS Q Series, Graphtec FC900, and Roland GR cutters.

- Smart Blade Landing: Some vinyl cutters have built-in media sensors that detect the surface of the loaded film. They can also control the force with which the blade contacts the vinyl. This combination of precise controls can give your blade the precision of a hand held art knife. These abilities are known as Smart Blade Landing in the Q Series. The Graphtec CE7000 cutting plotters and FC9000 series call this feature “tool soft landing intelligence”. This level of mechanical finesse is indispensable when cutting sensitive materials like window tint film. Because it limits wasted vertical motion of the tool holder, it also speeds throughput and prolongs the service life of the plotter.

- Media Pre-Feed: The ability to automatically advance a user-determined amount of media can save lots of time and money. It can also prevent damage to your vinyl cutter's drive motors. This feature, known as auto pre-feed or “area”, is normally found in the control panels of intermediate and advanced vinyl cutters. The user can enter the amount of vinyl desired so that, before the cutter begins a job, it feeds forward the specified amount of vinyl. Then retracts it back toward the roll. This process not only enables users to make sure the media is loaded correctly, but also places subtle grooves in the face film. These become subtle tracks that guide the pinch rollers as the cut job is processed. This increases the cutter’s tracking capabilities. It also pulls slack from the roll of media so that the plotter isn’t working against the weight and inertia of the roll. Cutting from a roll with no slack can produce stress on the drive mechanism and cause errors that interrupt production and damage the machine. If your cutter doesn’t have a pre-feed function in the menu, you’ll have to remember to do this by hand before sending each cut job.

Other features and considerations:

- Adjustable pinch rollers allow you to moderate the amount of pressure applied to media. Optimizing pressure enhances tracking on thicker materials like PVC sand blast stencil. Both the Q Series and FC9000, and Roland GR Series have adjustable pinch rollers.

- A media cut-off feature allows you to begin each job with a clean straight edge, reducing material waste. It also reduces the risk of damage to the platen caused by taking a blade to the front of your plotter. This nifty function is found in Vinyl EXPRESS Q Series, Graphtec FC9000, and Roland GR vinyl cutters.

- Warranty coverage. In a perfect world there would be no warranties needed. But ice cream is still fattening, we still have rainy days and Mondays, and vinyl cutters occasionally malfunction. That’s why all of our cutters come with warranty coverage ranging from six months to three years depending on the model. You can generally find the basic warranty listed at the bottom of a specifications chart.

Help when you need it The final consideration when choosing a vinyl cutter isn’t a feature on the equipment, it’s a feature of the vendor from whom you purchase it. Like good tracking and precise cutting, it can be critical to the efficient operation of your fledgling sign and graphics business. Choose a supplier who is ready, willing, and able to provide the technical support you’ll need as you negotiate the learning curve. SignWarehouse provides outstanding support for our legions of customers. Because we understand that one size doesn’t fit all, we offer a variety of Support options, depending on customer preference. Most vinyl cutters offered by SIGNWarehouse come with complimentary Gold Support to help you get up and running. Contact Us for prompt, professional product support. And every SignWarehouse customer receives free lifetime support via access to the Product Support Blog and knowledge base, including video tutorials, drivers, and more. Choosing your first vinyl cutter is a critically important decision. Even choosing your second or third should be done with thoughtful consideration of your needs and goals. Look beyond speed, force, and price. Determine how intricate and how long your graphics will be. Think about whether you need to manage very thin or very thick media. Consider the possible need to contour-cut printed images or produce perforated decals. And of course, weigh the importance of tech support and get the amount you think you’ll need to keep it all running smoothly. The more you understand your immediate and future needs, the more prepared you will be to choose the best vinyl cutter to help you meet the challenges of 21st century sign making.