As sign makers expand into new markets for vinyl decals, their customers are increasingly asking for digital color: photos, logos, and intricate designs. These require an inkjet printer. If you're at this stage in your digital graphics journey, you may be wondering what kind of vinyl you need. What works with your printer, and what kind of vinyl is right for your job? How do you determine what separates good printable vinyl from not-so-good. If these questions sound familiar, you are in the right place. We're about to answer all of these and more. This is your Basic Guide to Printable vinyl.

Types of ink: Aqueous, Eco-solvent, Latex, UV

Before you can decide what kind of vinyl to buy for your inkjet printer, you have to know what kind of ink your printer uses. Not all vinyl is compatible with all kinds of ink. There are several different kinds of inks used in large format digital printing. More importantly, there are two basic categories of media; coated and un-coated. This is important because some kinds of ink require coated media and some don't.

It is vital that you understand whether your printer requires coated media so you can avoid costly and frustrating missteps. The four kinds of inks used in modern large format printing are aqueous, solvent-based, latex, and UV curable. This is a bit of an oversimplification. We'll get more into the details as we explore the differences.

Aqueous: Of these four types, only aqueous ink requires top-coated media. All of the others can be used with un-coated media. What happens if you try to use un-coated media in an aqueous inkjet printer?

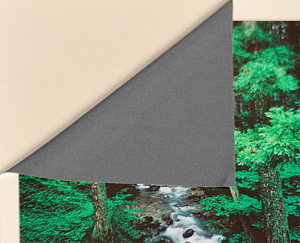

This happens (Fig 1). The ink never really dries. It may even puddle or run off the surface because the required coating isn't there to hold the ink droplets in place. There aren't as many printable vinyl options for aqueous inkjet printers. The other downside of using top-coated media is that the top-coat keeps the ink on the surface.

This is fine for indoor use, but when placed outdoors, the ink is exposed to the full effect of the sun's Ultraviolet radiation. This causes the ink to fade noticeably in a very short time. Pigment ink fades in a few months outdoors. Dye based inkjet prints may fade in weeks. Vinyl graphics printed with dye or pigment based aqueous ink require an added layer of clear coat or overlaminate film to be suitable for long-term outdoor use.

Solvent-Ecosolvent: solvent-based inks were made for the commercial sign industry. They include heat and chemical agents that allow the ink to penetrate the face film and deposit the resins beneath the surface. This means eco-solvent printers can print on coated or un-coated vinyls. This provides a wide range of compatible vinyls. Possible choices include everything from economy calendared vinyl for short term outdoor signs to premium cast vinyl for vehicle wraps.

There are also lots of specialty vinyls including wall vinyl, high-tack vinyl for low energy surfaces, one-way view perforated vinyl and just about any other application you can imagine. The solvents also help to protect the ink from the sun's UV radiation. The result is an outdoor life of up to three years without any lamination or clear coat and up to five years with lamination.

Latex: Latex is a bit of a hybrid. It's a water-based ink that uses high temperatures to evaporate the water and encapsulate the resins on the surface of the media. There are no specific outdoor durability ratings published for Latex, but HP asserts that the prints are comparable to eco-solvent in UV resistance. The range of Latex compatible vinyl is greater than that for traditional aqueous inkjet printers, but not as wide as eco-solvent.

The main limitation for Latex compatible vinyl is the high temperature required to dry and encapsulate the ink. Latex printers subject the media to temperatures as high as 257°F, which is twice as much heat as that used in eco-solvent printers . This can cause warping, image distortion, and other issues. Not all solvent printable vinyl is Latex compatible. If you're using a Latex inkjet printer, make sure the media you want is compatible before you purchase. More on that in a moment.

UV Curable: The other ink used in sign industry applications is UV curable ink. UV curable ink is a unique formula that is encapsulated by ultraviolet light in a specific wavelength resulting in prints that are instantly dry and somewhat abrasion-resistant.

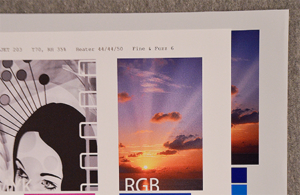

UV ink can also be used very effectively to print directly to uncoated media. However, the instant curing of the ink makes it fairly inflexible, so the bulk of UV printers currently in use are designed for printing on rigid substrates like sign blanks, plaques, and wood (Fig 2). There are some UV and UV-LED printers that use flexible ink. Flexible UV ink can be printed on vinyl and used for standard vinyl applications including window decals and fleet graphics. But these are the exception, not the rule. If you have purchased a UV printer and would like to print on vinyl, contact your equipment vendor and find out if your ink is flexible or non-flexible.

If you are considering purchasing a a UV-LED printer and would like to use it for vehicle wraps or other challenging vinyl applications, make sure you ask about the flexibility of the ink before you sign on the dotted line. The SIGNWarehouse catalog uses an easy legend to denote what vinyls are compatible with these four types of ink. Using this guide, we see that PrismJET 201 and 203 are compatible with eco-solvent, Latex, and some UV curable inks. Avery MPI 1105 EZRS wrap vinyl is compatible with eco-solvent and Latex inks, but not UV. Quick note: All of the information above applies to both sign vinyl and heat transfer film, aka T-shirt vinyl. From here on, we'll only be dealing with sign vinyl.

Types of Printable Vinyl. Cast, calendared, & Specialty

In addition to the differences in ink compatibility, printable vinyls can be categorized by the basic properties of the face film. We can classify printable vinyl in the same three categories we use for plotter vinyls; Cast, calendared, and specialty vinyls. For a complete explanation of the differences between cast and calendared vinyl, please bookmark this article for future reference. Here's a brief summary.

Calendared vinyl: Calendared vinyl is so named because it's made by squeezing a mass of PVC through a stack of rollers or calendars.

The heat and pressure squeeze the mass down into a sheet of material that is about 2.5 - 3 mil (0.003") thick (Fig 3). Because it's born in pressure and heat, calendared vinyl is inherently unstable. It's best suited for application on flat surfaces or simple curves. Outdoor durability generally ranges from two to six years. Some economy calandared vinyls such as ORAJET 3621 and 3640 are good for short term outdoor graphics. Intermediate calendared vinyls are more flexible and durable. These can be used on more challenging curved surfaces and will last longer in the elements before shrinking, cracking, or peeling. Printable intermediate calendared vinyls include PrismJET 201, 203, 222, and ORAJET 3651, and 3164. These are all excellent choices for indoor and outdoor printed vinyl signs and graphics.

Cast Vinyl: cast vinyl is made by pouring a liquid mixture of PVC and plasticizers onto a moving web. As the liquid passes through an oven, the moisture evaporates and leaves behind a thin layer of vinyl, generally 2mil thick. Because it's made without stressing the film, cast vinyl has excellent dimensional stability. That and the thin 0.002" face film make it ideal for application on compound curves. Think motorcycle helmets, and VW Beetle fenders. These are the vinyls generally used for applying vehicle wraps.

Printable cast vinyls also include other features like air egress release liners and an excellent white point for high resolution printing. These will be discussed a little later. Examples of excellent premium cast vinyl are 3M ControlTac, ORAJET 3951RA, and the aforementioned Avery MPI 1105. Because of their high tech construction and demanding applications, these are among the most expensive printable vinyls on the market. Prices generally range around $1.00 per square foot.

Ultra-calendared: The competitive world of vehicle wraps has created demand for a more affordable printable vinyl that can be used for some wrap applications that don't require the conformability of a premium cast film.

To meet this demand we offer two ultra-calendared vinyls for vehicle wraps, PrismJET 230 Ultra and ORAJET 3551RA. These products are ideal for wrapping vehicles with flat or moderately curved surfaces. Think box trailers and pickup trucks. And at only 61¢/square foot, it's a great option for a competitive market.

Specialty Printable Vinyls: That brings us to the catch-all category. Specialty vinyls are those with unique features and applications. These include perforated vinyls used for one way view graphics and high-tack vinyls made for decorating low energy substrates. Printable reflective vinyls might also be tossed in this bucket. Here are a few examples of specialty vinyls we stock for eco-solvent printing.

- Perforated vinyls: These are vinyls that have perforated face film. The original version had half of the surface area removed. These are called one-way-view vinyls because when viewed from the printed side, the printed image is visible and the application is opaque. But when viewed from the opposite side, the effect is similar to window tint film. The back of the film is effectively translucent. We carry several varieties of perforated vinyl ranging from the standard 50/50 punch pattern to new high resolution 80/20 patterns that produce more legible and effective graphics. There are even some inside-mount perforated vinyls with the adhesive on the print side. These can be mounted on the inside of a window for vandal-proof storefront marketing.

- Reflective: We offer several reflective vinyls that are fully compatible with eco-solvent ink. These are finding use in traditional applications like police and emergency vehicles, but also as high impact graphic elements in commercial and custom vehicle wraps. We offer EnduraLITE R8512, which is very conformable, EnduraLITE 48000, and ORALITE 5600 and 5650RA for these applications. If you're using EnduraLITE 48000 or ORALITE 5600, your only print option is white. Never try to print on colored vinyl with CMYK ink. Here's why.

- High-Tack Vinyl: Lots of our customers and their customers want to put printed logos and decals on low energy substrates like coolers and concrete. The standard adhesives used in the sign industry are engineered for use on smooth, flat, non-porous surfaces. Getting them to stick to stucco requires a special high-grip adhesive such as the one on PrismJET 203HT. ORACAL also offers high tack versions of ORAJET 3951 and 3165 which are available by special order.

Vehicle Wraps and Air Egress Liners

There's another special feature found on some printable vinyls that warrants mention in its own category. The Air egress liners pioneered by Avery for easy application of vehicle wraps are appearing on a wide variety of cast and calendared printable vinyls. It's kind of like the trickle down phenomenon in automotive manufacturing. Features like heated leather seats, once found on premium luxury sedans, eventually become available to the mass market. What is air egress and why is it spreading?Air egress liners solve one of the most vexing problems in vehicle wrap installation. They allow installers to apply large panels of vinyl to bare metal without getting air bubbles trapped underneath. Trapped air can easily be pushed out from under the applied vinyl through minute channels in the adhesive. This feature saves lots of time and aggravation. The downside of air egress is a slight texture visible in the face film. Depending on the product, this can be a slight distraction or a glaring disappointment.

Naturally some people wondered, if it's good for speeding up vehicle wraps, why can't it be used for other large vinyl graphics? Now it can. There are lots of intermediate calendared print vinyls that have this feature. Our PrismJET 201AE and 203AE feature very fine micro-channels that avoid the tell-tale orange peel effect seen on most other air egress vinyls. The result is easier installation and outstanding print quality. Other air egress products include ORAJET 3165RA, 3651RA, 3169RA, and the aforementioned 3551RA. The other downside to air egress liners is difficulty using these vinyls with transfer tape. The channels in the liner turn what is usually a smooth flat surface into a slightly textured one. Standard application tapes tend to curl away from the liner which can make installation of printed decals on air egress vinyl challenging. American BiltRite has a solution in their AirMASK tape which is specially formulated to lay flat on air egress liners. It's a great companion product if you're creating print and cut decals on any air egress vinyl.

Quality Markers: You've probably noticed that we stock lots of different kinds of printable vinyls. With all these choices, you might begin to wonder how to choose the best one. Start by choosing the right kind of vinyl for your application. If your job requires adhesion on compound curves, or long-term outdoor exposure, opt for a cast vinyl. If you need adhesion on polypropylene or some other low energy surface, PrismJET 203HT is the obvious choice. For the everyday signs and graphics, for which almost any vinyl will do, how do you decide which one to try? There are some indicators of quality you should look for when you decide what to roll into your large format printer. Here's a short list of features to consider.

- Print quality: Obviously, you want your prints to look as good as possible. Your choices of ink, printer, resolution, choice of vinyl are part of the quality equation. Features like brightness and ink absorption are key to optimizing image quality. Generally speaking, the whiter the face film and the higher the ink limits, the better your image will be. Most cast vinyls excel in these metrics. PrismJET 201 and 203 also excel in maximizing the color gamut of your prints. Of course, if you're concerned about print quality, you are using the correct ICC profile for your vinyl aren't you? If not, please click here. Yes, we have a blog article for that too.

- Outdoor durability: For long term outdoor use, you want to pick a vinyl that will stand the test of time. Try to match the job requirements with the expected outdoor life of the film. Please remember that choosing a five or seven year vinyl does not extend the life of the ink! An unlaminated eco-solvent or Latex print on five year film will still only last about three years before fading becomes visible.

- Conformability: As noted above, cast vinyl is the king of conformability. Even among cast films, some are better than others. Avery's MPI1105 is an ultra conformable film suitable for the most challenging curves and recesses. If your job doesn't require a cast vinyl but has rivets and corrugations, an ultra-calendered vinyl like PrismJET 230 Ultra or ORAJET 3551RA will be a better choice than a standard calendared film.

- Adhesive: There is an entire blog article about the importance of vinyl adhesives. Although acrylic adhesive formulas are becoming more advanced and durable, the conventional wisdom is still on the side of solvent-based adhesives. They tend to bond more quickly than acrylic and are more user-friendly with application fluids. There is an important difference between permanent, removable, and repositionable adhesives. Pick the best fit for your application. And remember, all adhesives become permanent if left in place long enough.

- Consistency: The final element to consider is consistency. Nothing frustrates a sign maker like getting a bad roll of vinyl. That's why we work hard to partner with respected manufacturers who produce consistent quality. Brands like PrismJET and ORAJET are popular with our customers partly because they're so reliable. This too should be a key factor in your print vinyl decisions.