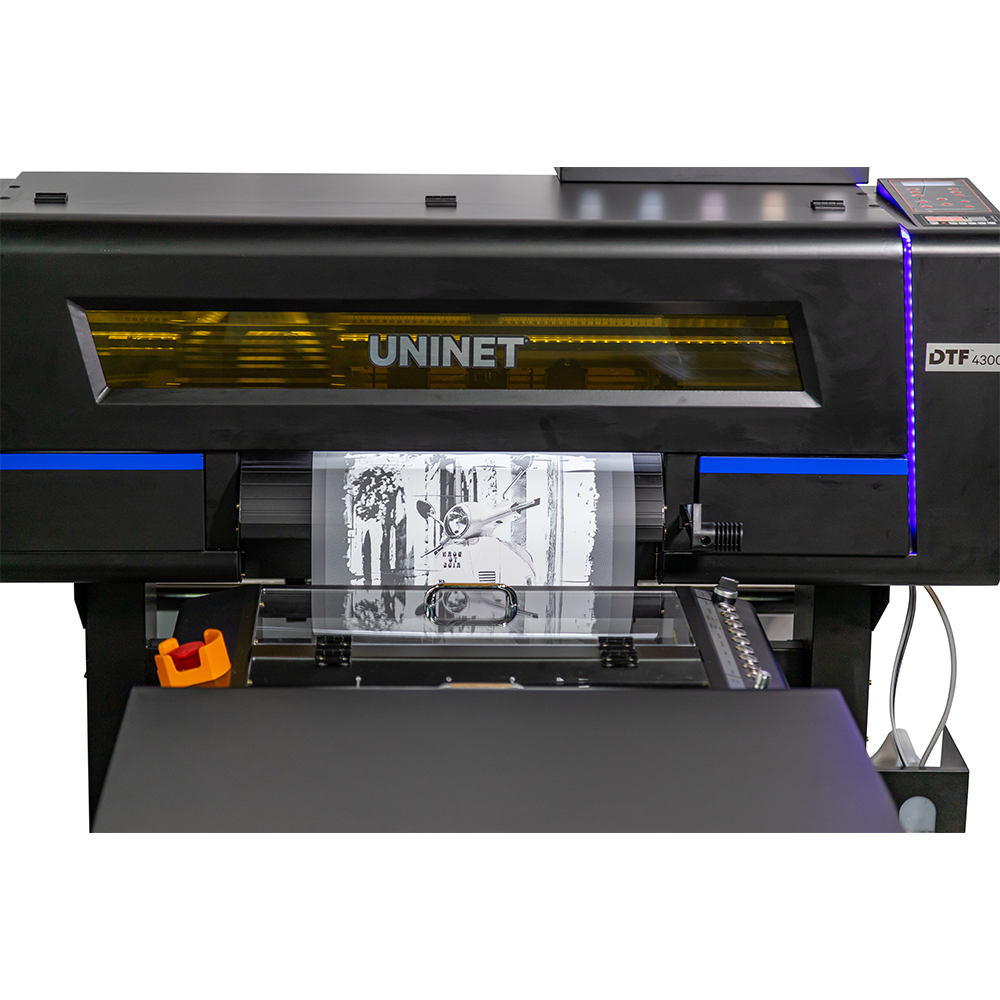

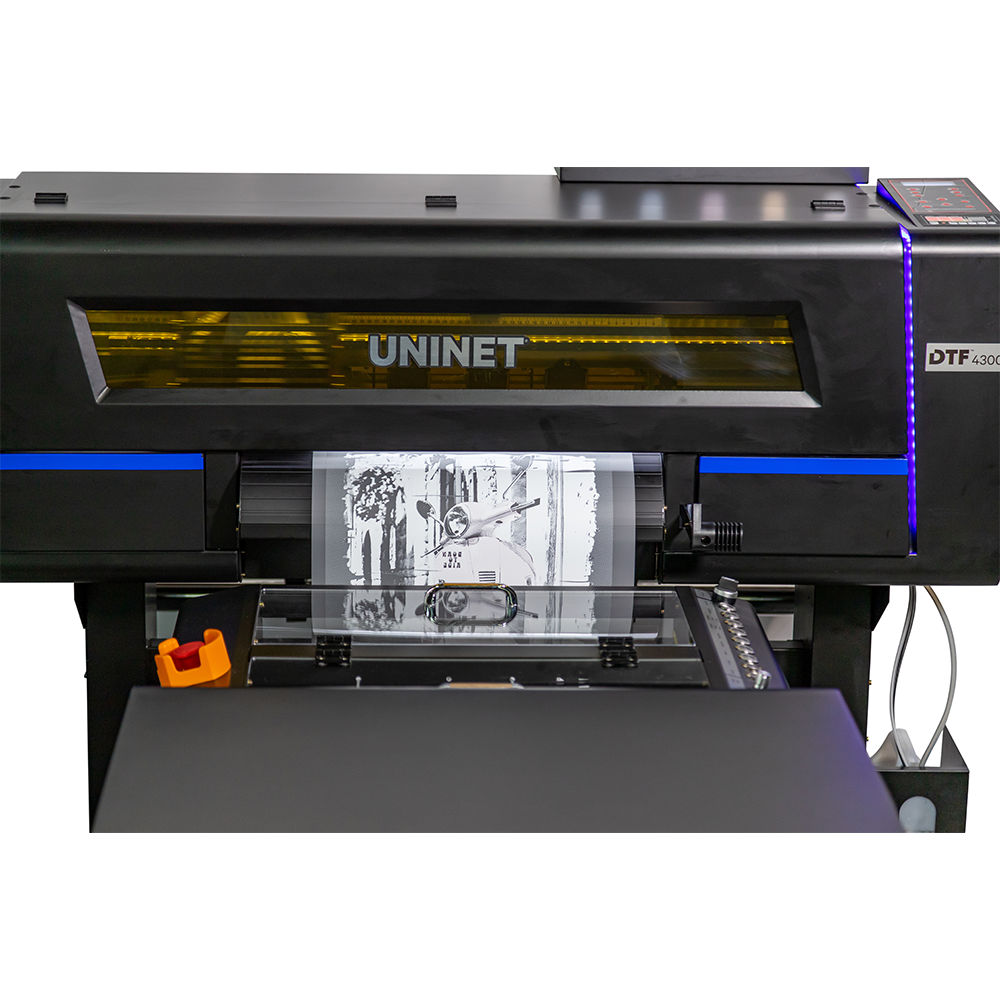

UNINET DTF 4300 Direct to Film Printer

Couldn't load pickup availability

Orders exceeding the stock on hand amount are processed as special orders, which require additional processing and shipping time and are not eligible for return.

Special Offer!

SignWarehouse PRO

Become one of our PRO members and get $549.75 back on this purchase and more! Learn how

The UNINET DTF 4300 elevates the garment industry with its cutting-edge, high-performance technology for medium to large-scale industrial use. Upgraded with an expansive 17 inch wide roll feed system, the printing capability allows for a wider array of garment and accessory applications. Let your creativity run free and allow for the most stunning quality and customized apparel to impress your customers.

Whether you are creating simple and detailed designs or elaborate colorful masterpieces, the UNINET 4300 allows for a dazzling alternative to other applications that take time to weed and apply. The ability to apply to dark or light colors and a massive array of fabrics, cotton, polyester, leather, canvas, spandex, linen, and so much more makes the UniNET 4300 DTF printer a solid option for any thriving garment business that is looking for high-productivity.

Boasting its industrial-grade dual print head design and tiny dot gain, The UNINET DTF 4300 printing system can produce high-definition prints and excellent color fidelity. Using a combination of five inks, which considerably increases the number of colors conceivable, this technology uses an automated process to lay down layers of CMYK colors and print white as overprint, all in a single pass, resulting in professional, unrivaled print quality and sharpness.

The UNINET DTF 4300 is not just a printer! It's a complete DTF startup solution that includes ProRIP advanced RIP software, 2-hr virtual onboarding, five-color 1000 ml bottles, transfer powder, DTF film roll, and a 12-month warranty.

Features:

- Accepts DTF rolls up to 17 inches wide

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling

- WICS (White Ink Circulation System) to minimize clogging

- Two high-definition industrial-grade inkjet printheads

- Continuous XL ink take feed system

- Humidity sensor

- RIP and Roller software included

- Advanced bi-directional media roller system for easy and fast feed controls

- Setup assistance and Master Class training included

Please Note: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use appropriate personal protective equipment since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Applications:

- Print and transfer on a wide variety of dark or light-colored fabrics, such as cotton, polyester, spandex, vinyl, nylon, leather, canvas, linen, chemical fiber, and more

Create stunning and fashionable t-shirts, dresses, backpacks, caps, tote bags, decoration pillows, tennis shoes, sports performance gear, and more

Produce long-lasting, flexible, soft-touch, vividly colored digital transfers

Experience fast and cost-effective print production and automation with flawless results

Please Note: As with other types of printers regular cleaning maintenance is essential. Failing to perform regular maintenance can result in costly printer repairs. Performing cleanings at the end of each day is essential, especially for the capping station as it prevents a thin film of ink from forming which can inhibit proper capping. Using the recommended cleaning solution and cleaning swabs to perform these tasks will help maintain a healthy printer. Regular maintenance should be performed on a daily basis to ensure printer output doesn’t diminish.

| UNINET DTF 4300 Specifications | |

| Print head | Two high-definition, professional piezo inkjet print head |

| Maximum Resolution | up to 1440 dpi |

| Print Speed | up to 44-50 sq ft/hr |

| Ink type | CMYK+ White with bulk ink system |

| Paper Capacity | 328 ft transfer roll x 17 in wide |

| Maximum Film Roll Width | 17 inches |

| Interface | Ethernet Port |

| Rated Current | 7A |

| Power | 120V |

| Dimensions | 53 in x 35 in x 53 in |

| Shipping Crate Dimensions | 67 in x 32 in x 23 in |

| Printer Weight | 286 lbs |

| Shipping weight | 375 lbs |

| Bundled Software | UNINET DTF ProRIP |

| Compatible OS | Windows® 10 & Windows® 11 |

| Warranty | USA Warranty, parts & labor |

| Support | DTF Master Class Video Training, One year complimentary Gold Support |

| Starter Bundle Includes | CMYK+W Bulk Ink system, DTF 17" x 328ft roll of transfer film, DTF adhesive powder, maintenance solutions and accessories |

| Things you may need that aren't included | UNINET DTF Powder Heat Station, HEPA filter or fume extractor*, heat press (16" x 20" heat platen recommended), small funnels, humidifier. |

UNINET DTF 4300 Printing System Includes:

UNINET® DTF™ ProRIP™ Advanced RIP Software - features exceptional file preparation, white and color management, production automation functionality, and more. (Built-in Ethernet Port on PC is Required).

2-hour virtual onboarding (soon to be replaced or enhanced with the UNINET DTF™ Master Class Video Training Series)

UNINET® DTF™ Five-color Inks- 1000 ml bottles.

UNINET® DTF™ Transfer Powder 2x 1.75 ml bottles.

UNINET® DTF™ Transfer Film Roll – 328 Ft Roll.

UNINET® DTF™ Starter Bundle (Hygrometer, Maintenance Solutions and Accessories).

World Class Service and Support direct from UNINET.

UNINET® USA 12-month warranty.

Lifetime Phone Support Included ‡

‡ Lifetime is used to define the duration of time during which the product is available for sale.

Things you may need that are NOT included: UNINET DTF Powder Heat Station, HEPA filter or fume extractor*, Heat Press (16 in x 20 in heat platen recommended), small funnels, humidifier.

*NOTE: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use protective gear since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Overview

The UNINET DTF 4300 elevates the garment industry with its cutting-edge, high-performance technology for medium to large-scale industrial use. Upgraded with an expansive 17 inch wide roll feed system, the printing capability allows for a wider array of garment and accessory applications. Let your creativity run free and allow for the most stunning quality and customized apparel to impress your customers.

Whether you are creating simple and detailed designs or elaborate colorful masterpieces, the UNINET 4300 allows for a dazzling alternative to other applications that take time to weed and apply. The ability to apply to dark or light colors and a massive array of fabrics, cotton, polyester, leather, canvas, spandex, linen, and so much more makes the UniNET 4300 DTF printer a solid option for any thriving garment business that is looking for high-productivity.

Boasting its industrial-grade dual print head design and tiny dot gain, The UNINET DTF 4300 printing system can produce high-definition prints and excellent color fidelity. Using a combination of five inks, which considerably increases the number of colors conceivable, this technology uses an automated process to lay down layers of CMYK colors and print white as overprint, all in a single pass, resulting in professional, unrivaled print quality and sharpness.

The UNINET DTF 4300 is not just a printer! It's a complete DTF startup solution that includes ProRIP advanced RIP software, 2-hr virtual onboarding, five-color 1000 ml bottles, transfer powder, DTF film roll, and a 12-month warranty.

Features:

- Accepts DTF rolls up to 17 inches wide

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling

- WICS (White Ink Circulation System) to minimize clogging

- Two high-definition industrial-grade inkjet printheads

- Continuous XL ink take feed system

- Humidity sensor

- RIP and Roller software included

- Advanced bi-directional media roller system for easy and fast feed controls

- Setup assistance and Master Class training included

Please Note: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use appropriate personal protective equipment since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Applications

Applications:

- Print and transfer on a wide variety of dark or light-colored fabrics, such as cotton, polyester, spandex, vinyl, nylon, leather, canvas, linen, chemical fiber, and more

Create stunning and fashionable t-shirts, dresses, backpacks, caps, tote bags, decoration pillows, tennis shoes, sports performance gear, and more

Produce long-lasting, flexible, soft-touch, vividly colored digital transfers

Experience fast and cost-effective print production and automation with flawless results

Please Note: As with other types of printers regular cleaning maintenance is essential. Failing to perform regular maintenance can result in costly printer repairs. Performing cleanings at the end of each day is essential, especially for the capping station as it prevents a thin film of ink from forming which can inhibit proper capping. Using the recommended cleaning solution and cleaning swabs to perform these tasks will help maintain a healthy printer. Regular maintenance should be performed on a daily basis to ensure printer output doesn’t diminish.

Videos

Specifications

| UNINET DTF 4300 Specifications | |

| Print head | Two high-definition, professional piezo inkjet print head |

| Maximum Resolution | up to 1440 dpi |

| Print Speed | up to 44-50 sq ft/hr |

| Ink type | CMYK+ White with bulk ink system |

| Paper Capacity | 328 ft transfer roll x 17 in wide |

| Maximum Film Roll Width | 17 inches |

| Interface | Ethernet Port |

| Rated Current | 7A |

| Power | 120V |

| Dimensions | 53 in x 35 in x 53 in |

| Shipping Crate Dimensions | 67 in x 32 in x 23 in |

| Printer Weight | 286 lbs |

| Shipping weight | 375 lbs |

| Bundled Software | UNINET DTF ProRIP |

| Compatible OS | Windows® 10 & Windows® 11 |

| Warranty | USA Warranty, parts & labor |

| Support | DTF Master Class Video Training, One year complimentary Gold Support |

| Starter Bundle Includes | CMYK+W Bulk Ink system, DTF 17" x 328ft roll of transfer film, DTF adhesive powder, maintenance solutions and accessories |

| Things you may need that aren't included | UNINET DTF Powder Heat Station, HEPA filter or fume extractor*, heat press (16" x 20" heat platen recommended), small funnels, humidifier. |

UNINET DTF 4300 Printing System Includes:

UNINET® DTF™ ProRIP™ Advanced RIP Software - features exceptional file preparation, white and color management, production automation functionality, and more. (Built-in Ethernet Port on PC is Required).

2-hour virtual onboarding (soon to be replaced or enhanced with the UNINET DTF™ Master Class Video Training Series)

UNINET® DTF™ Five-color Inks- 1000 ml bottles.

UNINET® DTF™ Transfer Powder 2x 1.75 ml bottles.

UNINET® DTF™ Transfer Film Roll – 328 Ft Roll.

UNINET® DTF™ Starter Bundle (Hygrometer, Maintenance Solutions and Accessories).

World Class Service and Support direct from UNINET.

UNINET® USA 12-month warranty.

Lifetime Phone Support Included ‡

‡ Lifetime is used to define the duration of time during which the product is available for sale.

Things you may need that are NOT included: UNINET DTF Powder Heat Station, HEPA filter or fume extractor*, Heat Press (16 in x 20 in heat platen recommended), small funnels, humidifier.

*NOTE: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use protective gear since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Available Financing.

Receive Instant Approval.

Fill out our quick application and we'll reach out to discuss more info and next steps. Hurry, spots limited!