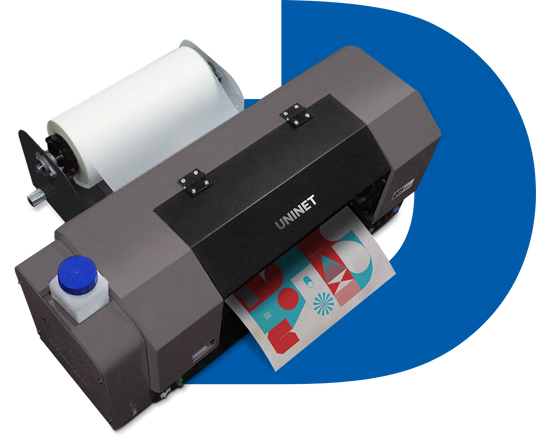

UNINET DTF 1000 Direct to Film Printer - Starter Bundle

Couldn't load pickup availability

Orders exceeding the stock on hand amount are processed as special orders, which require additional processing and shipping time and are not eligible for return.

Special Offer!

SignWarehouse PRO

Become one of our PRO members and get $217.50 back on this purchase and more! Learn how

The UNINET DTF 1000 is a roll-fed 13-inch desktop DTF (Direct to Film) solution. It is built to perform for the short-volume production of exceptional quality, full-color print transfers for the digital apparel decorating market, which can be applied to light and dark-colored garments.

The DTF1000 is compact yet powerful, expertly configured for manual DTF powder application, and is capable of producing simple or intricate, colorful weedless digital transfers in a single pass. As an optional upgrade, the DTF™ 1000 can be paired with the *UNINET® DTF™ 1000 Auto-Powder Unit to enable fully automated powder application, curing, and drying for a comprehensive, high-volume printing solution.

The UNINET DTF 1000 is not just a printer! It's a complete DTF startup solution that comes with ProRIP software, ink bottles, PET film, transfer powder, supplies, setup assistance, and training.

Features:

- Roll-fed printer maximizes efficiency, 13-inch film supports pro-size transfers.

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling

- High-resolution photo-quality prints from advanced 1440dpi piezo print head

- Print speeds up to 13 square ft/hr.

- Six-channel piezo print engine supports CMYK plus white

- Automated WICS (White Ink Circulation System)

- Conveniently located front control panel

- XL White Ink Tank and Advanced Continuous Feed System

- DTF specialized Damper system for improved pressurized delivery of ink

- Humidity Sensor

- RIP and Roller Software Included

- Advanced bi-directional media roller system for easy and fast feed controls

- Setup assistance and Master Class training included

UNINET DTF Application Instructions

UNINET DTF Heat Station Instructions

Please Note: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use appropriate personal protective equipment since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Applications:

- Light and dark-colored apparel transfers

- Transfers to non-apparel textiles including tote bags and similar applications

DTF1000 samples available upon request. Use the Contact Us link to request a shirt sample or pre-printed transfer.

Please Note: As with other types of printers regular cleaning maintenance is essential. Failing to perform regular maintenance can result in costly printer repairs. Performing cleanings at the end of each day is essential, especially for the capping station as it prevents a thin film of ink from forming which can inhibit proper capping. Using the recommended cleaning solution and cleaning swabs to perform these tasks will help maintain a healthy printer. Regular maintenance should be performed on a daily basis to ensure printer output doesn’t diminish.

DTF Transfer printing combines the ease-of-use of plastisol transfers and the custom & short-run efficiency of direct-to-garment. The combination of DTF film and adhesive power makes it a more versatile garment decoration method than either.

DTF applications include vivid, colorful, stretchable, self-weeding heat transfers for

- Light and dark cotton apparel

- Light and dark Polyester apparel

- Light and dark blended apparel

- Other related textiles such as caps, tote bags, and pillow cases

Please Note: As with other types of printers regular cleaning maintenance is essential. Failing to perform regular maintenance can result in costly printer repairs. Performing cleanings at the end of each day is essential, especially for the capping station as it prevents a thin film of ink from forming which can inhibit proper capping. Using the recommended cleaning solution and cleaning swabs to perform these tasks will help maintain a healthy printer. Regular maintenance should be performed on a daily basis to ensure printer output doesn’t diminish.

DTF1000 samples available upon request. Use the Contact Us link to request a shirt sample or pre-printed transfer.

Overview

The UNINET DTF 1000 is a roll-fed 13-inch desktop DTF (Direct to Film) solution. It is built to perform for the short-volume production of exceptional quality, full-color print transfers for the digital apparel decorating market, which can be applied to light and dark-colored garments.

The DTF1000 is compact yet powerful, expertly configured for manual DTF powder application, and is capable of producing simple or intricate, colorful weedless digital transfers in a single pass. As an optional upgrade, the DTF™ 1000 can be paired with the *UNINET® DTF™ 1000 Auto-Powder Unit to enable fully automated powder application, curing, and drying for a comprehensive, high-volume printing solution.

The UNINET DTF 1000 is not just a printer! It's a complete DTF startup solution that comes with ProRIP software, ink bottles, PET film, transfer powder, supplies, setup assistance, and training.

Features:

- Roll-fed printer maximizes efficiency, 13-inch film supports pro-size transfers.

- Vacuum-enhanced printing area for better ink adhesion and avoidance of film buckling

- High-resolution photo-quality prints from advanced 1440dpi piezo print head

- Print speeds up to 13 square ft/hr.

- Six-channel piezo print engine supports CMYK plus white

- Automated WICS (White Ink Circulation System)

- Conveniently located front control panel

- XL White Ink Tank and Advanced Continuous Feed System

- DTF specialized Damper system for improved pressurized delivery of ink

- Humidity Sensor

- RIP and Roller Software Included

- Advanced bi-directional media roller system for easy and fast feed controls

- Setup assistance and Master Class training included

UNINET DTF Application Instructions

UNINET DTF Heat Station Instructions

Please Note: This equipment requires a well-ventilated area with a filtration system. When working with DTF products and processes, use appropriate personal protective equipment since fumes might be harmful. DTF inks and film/sheets need an adequate humidity environment - above 50% humidity is strongly advised to reduce the possibility of ink clogs and film buckling.

Applications

Applications:

- Light and dark-colored apparel transfers

- Transfers to non-apparel textiles including tote bags and similar applications

DTF1000 samples available upon request. Use the Contact Us link to request a shirt sample or pre-printed transfer.

Please Note: As with other types of printers regular cleaning maintenance is essential. Failing to perform regular maintenance can result in costly printer repairs. Performing cleanings at the end of each day is essential, especially for the capping station as it prevents a thin film of ink from forming which can inhibit proper capping. Using the recommended cleaning solution and cleaning swabs to perform these tasks will help maintain a healthy printer. Regular maintenance should be performed on a daily basis to ensure printer output doesn’t diminish.

Videos

Specifications

DTF Transfer printing combines the ease-of-use of plastisol transfers and the custom & short-run efficiency of direct-to-garment. The combination of DTF film and adhesive power makes it a more versatile garment decoration method than either.

DTF applications include vivid, colorful, stretchable, self-weeding heat transfers for

- Light and dark cotton apparel

- Light and dark Polyester apparel

- Light and dark blended apparel

- Other related textiles such as caps, tote bags, and pillow cases

Please Note: As with other types of printers regular cleaning maintenance is essential. Failing to perform regular maintenance can result in costly printer repairs. Performing cleanings at the end of each day is essential, especially for the capping station as it prevents a thin film of ink from forming which can inhibit proper capping. Using the recommended cleaning solution and cleaning swabs to perform these tasks will help maintain a healthy printer. Regular maintenance should be performed on a daily basis to ensure printer output doesn’t diminish.

DTF1000 samples available upon request. Use the Contact Us link to request a shirt sample or pre-printed transfer.

Downloadable Files

Meet the UNINET DTF 1000.

Ready to wear meets designer quality

Good things come in smaller packages.

Product Features

In Addition, the printing system features

A LOOK AT THE NEW UNINET DTF PRODUCT LINE

BEYOND THIS, UNINET PROVIDES

CONTENTS

What’s included in the PrismJET 54 Gen2 Pro Package?

What kind of materials can I print on?

Can I print and cut directly from my computer?

Is the 64" GCC Jaguar V easy to use?

Available Financing.

Receive Instant Approval.

Fill out our quick application and we'll reach out to discuss more info and next steps. Hurry, spots limited!